Quality and Logistics

Maintaining a customer satisfaction rate approaching 100%

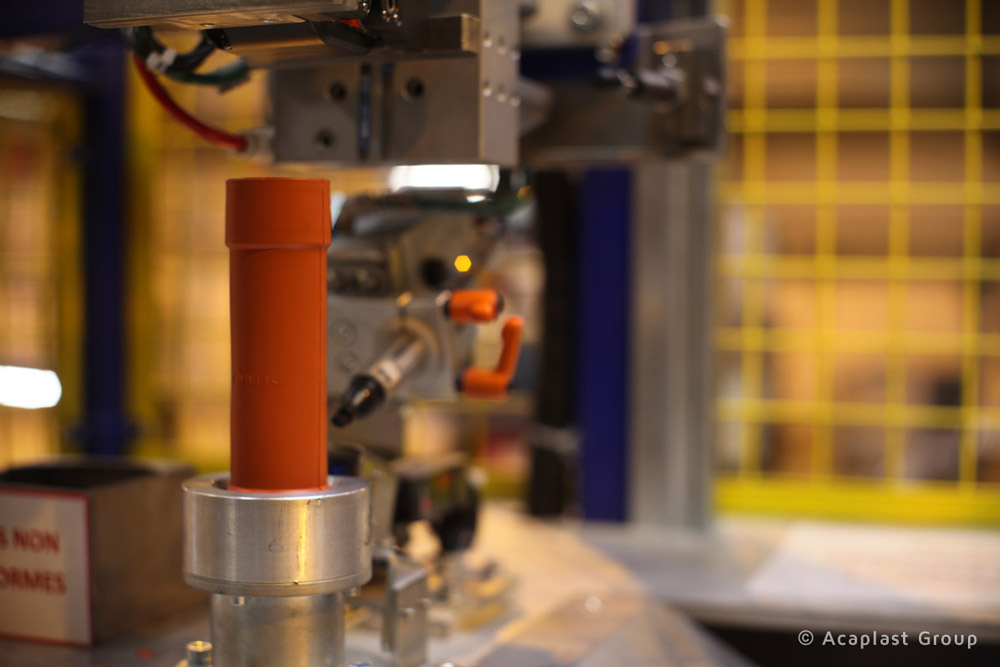

At Acaplast, the quality of parts and logistics performance are constantly measured through OTD and PPM indicators. We pay close attention to our performance reviews, which reflect customer satisfaction rates. Acaplast implements continuous improvement processes to monitor and enhance the quality of customer support in the supply of plastic, rubber and LSR parts, or more complex assembled or overmolded components.

Management systems

- EDI integration of customer programs

- Processing EDI messages

- FIFO inventory management

- Just in time delivery

Certifications

- ISO 9001

- IATF 16949

EXPERT OPINION

For ACAPLAST, quality is much more than a concept or a set of standards and certifications: it is a culture. Our quality management takes into account the diversity of production inherent in our 9 production sites, which are divided between rubber compounding, plastic part injection and technical rubber part molding workshops. At each site, we take into account the specific considerations of each location in monitoring our performance.